- Dual Channels of 1.5G hi-data rate signal link

- Single lower data rate signal channel

- Compact size & Light weight

![]()

- ・Dual channels of 1.5G high data rate signal transmission are suitable for multi sensor solutions such as surveillance/security systems.

- ・A single lower data rate signal channel can be used for controlling signal transmission.

- ・Durable in harsh environments. (see specifications)

![]()

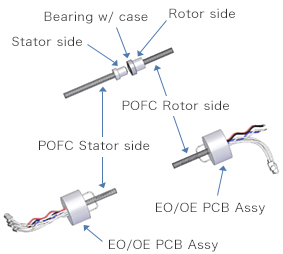

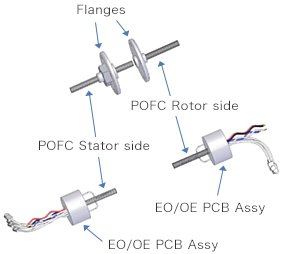

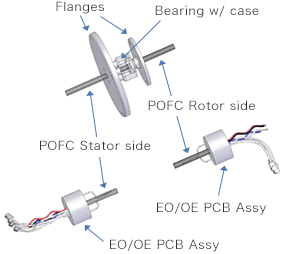

| Single bearing | w/o bearing | double bearings |

|---|---|---|

|

|

|

| "The single bearing POFC-D2-U1" has its signal path coupling inside the bearing. Customers can integrate the unit into their structures to make a rotational signal transmission joint. |

"The bearingless POFC-D2-U1" is designed to be integrated into customers' bearings. Depending on the size of the bearings, we can offer different unit sizes for the right fit. | "The double bearing POFC-D2-U1" can be used when there is an existing bearing in customers' structures. The POF-Coupling unit can be integrated into such structure without disturbing the functionality of the two bearings, yet giving it a rotational signal transmission joint . |

| Electrical characteristics | |

|---|---|

| High speed signal transmission channel | 1.5Gbps Uni-directional 2 channels (Rotor ⇒ Stator) |

| Low speed signal transmission channel | 38.4Kbps Uni-directional 1 channel (Stator ⇒ Rotor) |

| Power input (*1) | +3.3V +/-5% |

| Mechanical characteristics | POFC-D2-U1 w/ bearing | POFC-D2-U1 w/o bearing | POFC-D2-U1 double bearings |

|---|---|---|---|

| Dimensions(dia.x h) & Weight (Optical Rotary Joint) | φ8 x 4.5/16g | φ23 x 25(MAX)/21g | φ23 x 25(MAX)/21g |

| Dimensions(dia.x h) & Weight (EO/OE PCB Assy) | φ16 x 10(x2) | ||

| Load limitation to the bearings | Thrust load: 9.8N(MAX) | Not specified (*3) | Not specified (*3) |

| Rotation speed(rpm) | 100rpm | ||

| Environmental | |

|---|---|

| Temperature range | -40/+85deg C |

| Vibration resistance | 10Hz - 2000Hz 147m/s² |

| Shock resistance | 294m/s² 11ms |

(*1) The power for RLC® is required at the rotor side and the stator side.

(*2) Diameter may differ depending on frame thickness.

(*3) Depending on customer bearings' characteristics.

(*4) For faster rotation speed, please consult our customer support.

![]()

| # | Color | Symbol | Description | Cablespec. |

|---|---|---|---|---|

| 1 | Yellow | GND | Ground | UL AWG30 |

| 2 | Black | +3.3V_IN | +3.3V Input | UL AWG30 |

| 3 | White | SG | Low data rate signal Ground | UL AWG30 |

| 4 | Blue | SIG1 | Low data rate signal Input (3.3V-LVCMOS) | UL AWG30 |

| 5 | White | Rx1+ | Differential signal Output+ | U.FL-2LP-04 (Impedance 50ohm) |

| 6 | Black | Rx1- | Differential signal Output- | |

| 7 | White | Rx2+ | Differential signal Output+ | |

| 8 | Black | Rx2- | Differential signal Output- |

| # | Color | Symbol | Description | Lead Wire |

|---|---|---|---|---|

| 1 | Yellow | GND | Ground | UL AWG30 |

| 2 | Black | +3.3V_IN | +3.3V Input | UL AWG30 |

| 3 | White | SG | Low data rate signal Ground | UL AWG30 |

| 4 | Blue | SIG1 | Low data rate signal Output (3.3V-LVCMOS) | UL AWG30 |

| 5 | White | Tx1+ | Differential signal Input+ | U.FL-2LP-04 (Impedance 50ohm) |

| 6 | Black | Tx1- | Differential signal Input- | |

| 7 | White | Tx2+ | Differential signal Input+ | |

| 8 | Black | Tx2- | Differential signal Input- |